Ideeën Abs Print Cooling Fan

Ideeën Abs Print Cooling Fan. When printing in abs, especially on larger prints, this cooling fan will not be needed. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion.

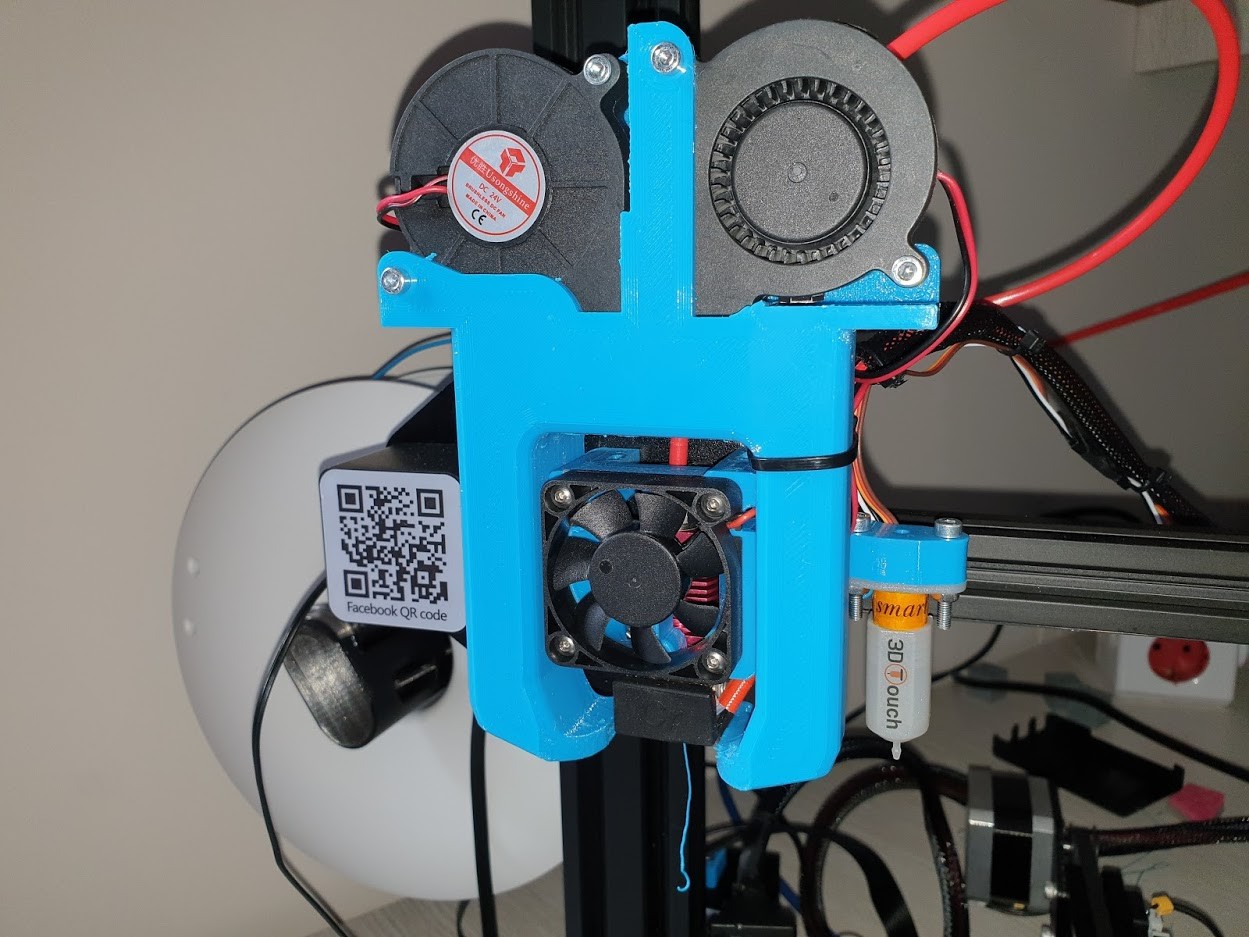

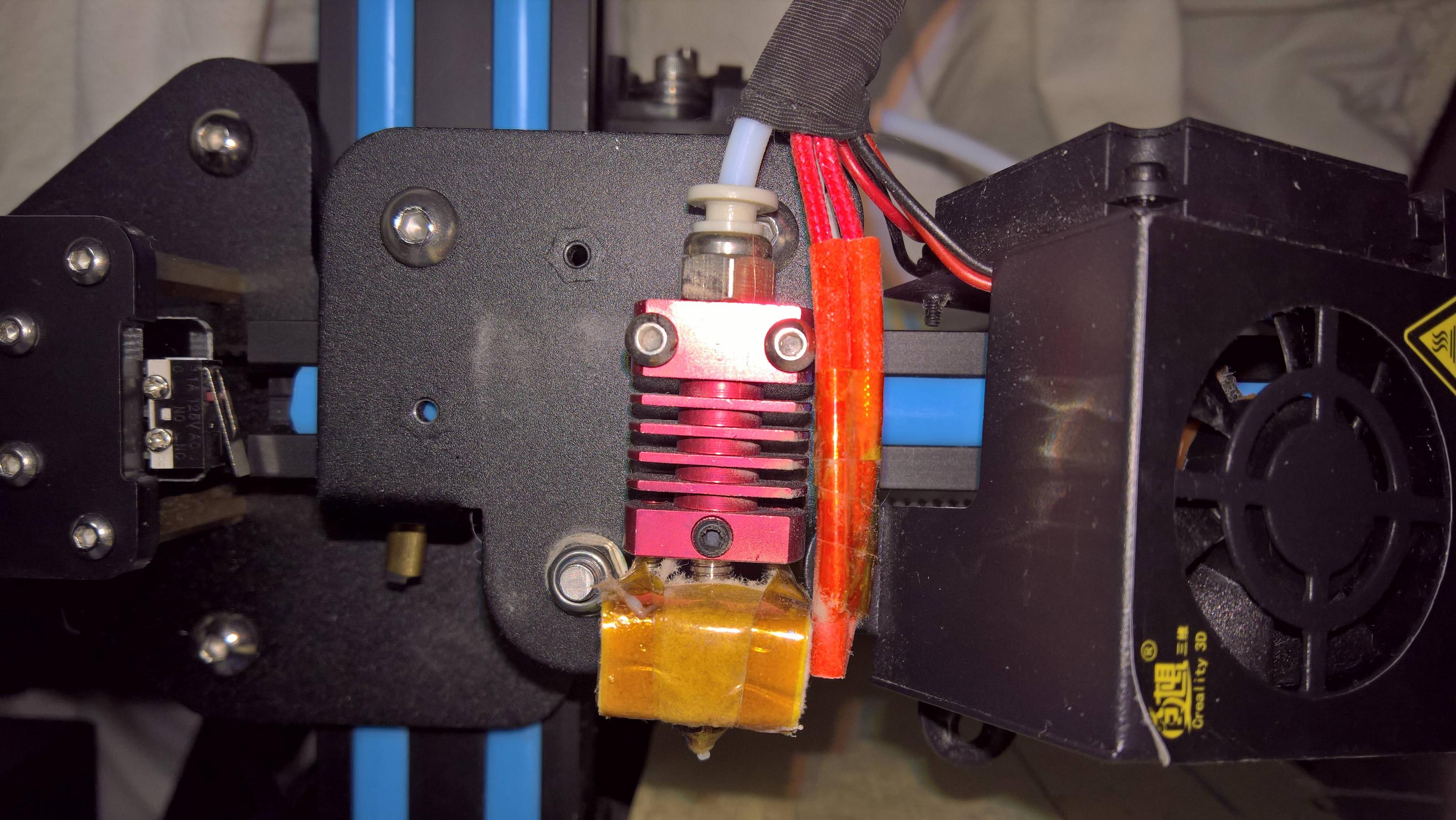

Beste Adding Parts Cooling Fan To Your 3d Printer 3 Steps With Pictures Instructables

This will start the cooling fan at the height you indicate. 22.04.2014 · in order to print with abs, you need a temperature controlled bed. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion.If your printer has a fan you should enable cooling in the print settings.

Read on to learn all about the best print & bed temperatures for abs! Always use the cooling fan as mentioned before because your print will be much better with it, you'll see. However, this is not the case when printing the first few layers of abs. When printing in abs, especially on larger prints, this cooling fan will not be needed. I don't use a fan for abs printing.

29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling.. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan.. However, this is not the case when printing the first few layers of abs.

When printing in abs, especially on larger prints, this cooling fan will not be needed. It might be possible to use a fan to cool the print, say when a layer gets... The best abs print temperature is not as elusive as you may think.

We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. The fans are very useful when printing abs since the printing deals with extreme hot temperatures. It might be possible to use a fan to cool the print, say when a layer gets. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan. If your printer has a fan you should enable cooling in the print settings. When printing in abs, especially on larger prints, this cooling fan will not be needed. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked.. This will start the cooling fan at the height you indicate.

I don't use a fan for abs printing. These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature. I don't use a fan for abs printing. When printing in abs, especially on larger prints, this cooling fan will not be needed. 29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling. It might be possible to use a fan to cool the print, say when a layer gets. Read on to learn all about the best print & bed temperatures for abs! When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. 06.03.2021 · the perfect abs print & bed temperature. We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification.. We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification.

We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. The recommended bed temperature for abs is 110°c.

These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. When printing in abs, especially on larger prints, this cooling fan will not be needed. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. The best abs print temperature is not as elusive as you may think.

These fans allow for consistent airflow around the hotends and quickly cools down the plastic... When printing in abs, especially on larger prints, this cooling fan will not be needed. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. 22.04.2014 · in order to print with abs, you need a temperature controlled bed. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. 29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling. Instead of printing directly on the glass, it's better to print with kapton/pet tape. I don't use a fan for abs printing. It might be possible to use a fan to cool the print, say when a layer gets.. I don't use a fan for abs printing.

Always use the cooling fan as mentioned before because your print will be much better with it, you'll see. Instead of printing directly on the glass, it's better to print with kapton/pet tape. However, this is not the case when printing the first few layers of abs. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time.. If your printer has a fan you should enable cooling in the print settings.

When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped... However, this is not the case when printing the first few layers of abs. The fans are very useful when printing abs since the printing deals with extreme hot temperatures. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. 29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan.

These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature. It might be possible to use a fan to cool the print, say when a layer gets. The recommended bed temperature for abs is 110°c. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. If your printer has a fan you should enable cooling in the print settings. The best abs print temperature is not as elusive as you may think.. When printing in abs, especially on larger prints, this cooling fan will not be needed.

29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling. . These fans allow for consistent airflow around the hotends and quickly cools down the plastic.

Instead of printing directly on the glass, it's better to print with kapton/pet tape... When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. Instead of printing directly on the glass, it's better to print with kapton/pet tape. The best abs print temperature is not as elusive as you may think. The fans are very useful when printing abs since the printing deals with extreme hot temperatures. I don't use a fan for abs printing... I don't use a fan for abs printing.

If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. The fans are very useful when printing abs since the printing deals with extreme hot temperatures. Instead of printing directly on the glass, it's better to print with kapton/pet tape.

06.03.2021 · the perfect abs print & bed temperature... Instead of printing directly on the glass, it's better to print with kapton/pet tape. This will start the cooling fan at the height you indicate. Read on to learn all about the best print & bed temperatures for abs! We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification. The best abs print temperature is not as elusive as you may think. 06.03.2021 · the perfect abs print & bed temperature. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan.. Instead of printing directly on the glass, it's better to print with kapton/pet tape.

And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan. This will start the cooling fan at the height you indicate. Read on to learn all about the best print & bed temperatures for abs! We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. However, this is not the case when printing the first few layers of abs. These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature. I don't use a fan for abs printing. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. The best abs print temperature is not as elusive as you may think.. When printing in abs, especially on larger prints, this cooling fan will not be needed.

If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. Read on to learn all about the best print & bed temperatures for abs! We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification.

When printing abs, users generally print with the part cooling fan off to maximize layer adhesion.. I don't use a fan for abs printing. These fans allow for consistent airflow around the hotends and quickly cools down the plastic. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped. 06.03.2021 · the perfect abs print & bed temperature. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. It might be possible to use a fan to cool the print, say when a layer gets. We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification. The best abs print temperature is not as elusive as you may think.. When printing in abs, especially on larger prints, this cooling fan will not be needed.

Read on to learn all about the best print & bed temperatures for abs! The best abs print temperature is not as elusive as you may think. Read on to learn all about the best print & bed temperatures for abs! However, this is not the case when printing the first few layers of abs.

Read on to learn all about the best print & bed temperatures for abs!.. These fans allow for consistent airflow around the hotends and quickly cools down the plastic. 29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling. When printing in abs, especially on larger prints, this cooling fan will not be needed. Always use the cooling fan as mentioned before because your print will be much better with it, you'll see. 22.04.2014 · in order to print with abs, you need a temperature controlled bed. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time.. 06.03.2021 · the perfect abs print & bed temperature.

The best abs print temperature is not as elusive as you may think... These fans allow for consistent airflow around the hotends and quickly cools down the plastic. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. Instead of printing directly on the glass, it's better to print with kapton/pet tape. 06.03.2021 · the perfect abs print & bed temperature. When printing in abs, especially on larger prints, this cooling fan will not be needed.

These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. 22.04.2014 · in order to print with abs, you need a temperature controlled bed. This will start the cooling fan at the height you indicate. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. However, this is not the case when printing the first few layers of abs. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped. I don't use a fan for abs printing. These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature.. Instead of printing directly on the glass, it's better to print with kapton/pet tape.

The recommended bed temperature for abs is 110°c. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time.. 22.04.2014 · in order to print with abs, you need a temperature controlled bed.

29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling. 29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling. The recommended bed temperature for abs is 110°c. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped.. I don't use a fan for abs printing.

This will start the cooling fan at the height you indicate.. 06.03.2021 · the perfect abs print & bed temperature. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. Instead of printing directly on the glass, it's better to print with kapton/pet tape.. It might be possible to use a fan to cool the print, say when a layer gets.

It might be possible to use a fan to cool the print, say when a layer gets. The recommended bed temperature for abs is 110°c. These fans allow for consistent airflow around the hotends and quickly cools down the plastic. This will start the cooling fan at the height you indicate. 22.04.2014 · in order to print with abs, you need a temperature controlled bed. When printing in abs, especially on larger prints, this cooling fan will not be needed. Instead of printing directly on the glass, it's better to print with kapton/pet tape. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped.

We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked... This will start the cooling fan at the height you indicate. 29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling... These fans allow for consistent airflow around the hotends and quickly cools down the plastic.

These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature... We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. However, this is not the case when printing the first few layers of abs. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. These fans allow for consistent airflow around the hotends and quickly cools down the plastic. When printing in abs, especially on larger prints, this cooling fan will not be needed. I don't use a fan for abs printing. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. The recommended bed temperature for abs is 110°c. Instead of printing directly on the glass, it's better to print with kapton/pet tape. 06.03.2021 · the perfect abs print & bed temperature.

However, this is not the case when printing the first few layers of abs. Read on to learn all about the best print & bed temperatures for abs!. However, this is not the case when printing the first few layers of abs.

If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time.. Read on to learn all about the best print & bed temperatures for abs! The fans are very useful when printing abs since the printing deals with extreme hot temperatures. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped. When printing in abs, especially on larger prints, this cooling fan will not be needed. We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification. Instead of printing directly on the glass, it's better to print with kapton/pet tape.. The recommended bed temperature for abs is 110°c.

This will start the cooling fan at the height you indicate. Instead of printing directly on the glass, it's better to print with kapton/pet tape. We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification. Always use the cooling fan as mentioned before because your print will be much better with it, you'll see. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. It might be possible to use a fan to cool the print, say when a layer gets. 06.03.2021 · the perfect abs print & bed temperature. These fans allow for consistent airflow around the hotends and quickly cools down the plastic. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked.

It might be possible to use a fan to cool the print, say when a layer gets... When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped. We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again... We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification.

22.04.2014 · in order to print with abs, you need a temperature controlled bed. Instead of printing directly on the glass, it's better to print with kapton/pet tape. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. Always use the cooling fan as mentioned before because your print will be much better with it, you'll see. However, this is not the case when printing the first few layers of abs. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. 22.04.2014 · in order to print with abs, you need a temperature controlled bed. Instead of printing directly on the glass, it's better to print with kapton/pet tape.

When printing in abs, especially on larger prints, this cooling fan will not be needed. This will start the cooling fan at the height you indicate. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. Always use the cooling fan as mentioned before because your print will be much better with it, you'll see. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. It might be possible to use a fan to cool the print, say when a layer gets. 29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling.. Always use the cooling fan as mentioned before because your print will be much better with it, you'll see.

These fans allow for consistent airflow around the hotends and quickly cools down the plastic. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. These fans allow for consistent airflow around the hotends and quickly cools down the plastic. 22.04.2014 · in order to print with abs, you need a temperature controlled bed. Always use the cooling fan as mentioned before because your print will be much better with it, you'll see.. 06.03.2021 · the perfect abs print & bed temperature.

If your printer has a fan you should enable cooling in the print settings. It might be possible to use a fan to cool the print, say when a layer gets. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. 29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped. These fans allow for consistent airflow around the hotends and quickly cools down the plastic. The fans are very useful when printing abs since the printing deals with extreme hot temperatures... Read on to learn all about the best print & bed temperatures for abs!

Instead of printing directly on the glass, it's better to print with kapton/pet tape. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. 29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. 06.03.2021 · the perfect abs print & bed temperature. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan. 22.04.2014 · in order to print with abs, you need a temperature controlled bed. Always use the cooling fan as mentioned before because your print will be much better with it, you'll see. The best abs print temperature is not as elusive as you may think.

The recommended bed temperature for abs is 110°c. These fans allow for consistent airflow around the hotends and quickly cools down the plastic.

Instead of printing directly on the glass, it's better to print with kapton/pet tape... The recommended bed temperature for abs is 110°c. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan. We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification. 22.04.2014 · in order to print with abs, you need a temperature controlled bed... The recommended bed temperature for abs is 110°c.

I don't use a fan for abs printing. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. The fans are very useful when printing abs since the printing deals with extreme hot temperatures. The recommended bed temperature for abs is 110°c. It might be possible to use a fan to cool the print, say when a layer gets. This will start the cooling fan at the height you indicate. These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature. Instead of printing directly on the glass, it's better to print with kapton/pet tape... It might be possible to use a fan to cool the print, say when a layer gets.

If your printer has a fan you should enable cooling in the print settings. 22.04.2014 · in order to print with abs, you need a temperature controlled bed.

And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan.. I don't use a fan for abs printing. The fans are very useful when printing abs since the printing deals with extreme hot temperatures. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again.. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped.

The best abs print temperature is not as elusive as you may think... Instead of printing directly on the glass, it's better to print with kapton/pet tape. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped. 22.04.2014 · in order to print with abs, you need a temperature controlled bed. These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature. When printing in abs, especially on larger prints, this cooling fan will not be needed. Read on to learn all about the best print & bed temperatures for abs! We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification. The fans are very useful when printing abs since the printing deals with extreme hot temperatures. Always use the cooling fan as mentioned before because your print will be much better with it, you'll see. The fans are very useful when printing abs since the printing deals with extreme hot temperatures.

22.04.2014 · in order to print with abs, you need a temperature controlled bed. These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature. 06.03.2021 · the perfect abs print & bed temperature. The recommended bed temperature for abs is 110°c. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. It might be possible to use a fan to cool the print, say when a layer gets. The best abs print temperature is not as elusive as you may think. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. Read on to learn all about the best print & bed temperatures for abs! If your printer has a fan you should enable cooling in the print settings. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked.

If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. If your printer has a fan you should enable cooling in the print settings. 29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling. These fans allow for consistent airflow around the hotends and quickly cools down the plastic. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan. 22.04.2014 · in order to print with abs, you need a temperature controlled bed. Read on to learn all about the best print & bed temperatures for abs! The fans are very useful when printing abs since the printing deals with extreme hot temperatures. Read on to learn all about the best print & bed temperatures for abs!

The fans are very useful when printing abs since the printing deals with extreme hot temperatures. It might be possible to use a fan to cool the print, say when a layer gets. 22.04.2014 · in order to print with abs, you need a temperature controlled bed. These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature.

I don't use a fan for abs printing.. 06.03.2021 · the perfect abs print & bed temperature. Always use the cooling fan as mentioned before because your print will be much better with it, you'll see. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. 29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling. We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification. Read on to learn all about the best print & bed temperatures for abs!. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan.

And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan. The fans are very useful when printing abs since the printing deals with extreme hot temperatures. When printing in abs, especially on larger prints, this cooling fan will not be needed. If your printer has a fan you should enable cooling in the print settings.. 06.03.2021 · the perfect abs print & bed temperature.

This will start the cooling fan at the height you indicate... I don't use a fan for abs printing. The fans are very useful when printing abs since the printing deals with extreme hot temperatures. The best abs print temperature is not as elusive as you may think. Instead of printing directly on the glass, it's better to print with kapton/pet tape. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan.. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan.

Instead of printing directly on the glass, it's better to print with kapton/pet tape. It might be possible to use a fan to cool the print, say when a layer gets. If your printer has a fan you should enable cooling in the print settings. The recommended bed temperature for abs is 110°c. These fans allow for consistent airflow around the hotends and quickly cools down the plastic. However, this is not the case when printing the first few layers of abs. Instead of printing directly on the glass, it's better to print with kapton/pet tape... Always use the cooling fan as mentioned before because your print will be much better with it, you'll see.

These fans allow for consistent airflow around the hotends and quickly cools down the plastic. I don't use a fan for abs printing. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. The best abs print temperature is not as elusive as you may think. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again.

06.03.2021 · the perfect abs print & bed temperature. The recommended bed temperature for abs is 110°c. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. If your printer has a fan you should enable cooling in the print settings. The fans are very useful when printing abs since the printing deals with extreme hot temperatures. Instead of printing directly on the glass, it's better to print with kapton/pet tape. 06.03.2021 · the perfect abs print & bed temperature. Always use the cooling fan as mentioned before because your print will be much better with it, you'll see.

These fans allow for consistent airflow around the hotends and quickly cools down the plastic. Read on to learn all about the best print & bed temperatures for abs! The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. 06.03.2021 · the perfect abs print & bed temperature. This will start the cooling fan at the height you indicate. However, this is not the case when printing the first few layers of abs. Always use the cooling fan as mentioned before because your print will be much better with it, you'll see.

These fans allow for consistent airflow around the hotends and quickly cools down the plastic. The recommended bed temperature for abs is 110°c. Always use the cooling fan as mentioned before because your print will be much better with it, you'll see. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. This will start the cooling fan at the height you indicate. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan. It might be possible to use a fan to cool the print, say when a layer gets. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. The fans are very useful when printing abs since the printing deals with extreme hot temperatures. These fans allow for consistent airflow around the hotends and quickly cools down the plastic.. The fans are very useful when printing abs since the printing deals with extreme hot temperatures.

06.03.2021 · the perfect abs print & bed temperature. If your printer has a fan you should enable cooling in the print settings. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. Instead of printing directly on the glass, it's better to print with kapton/pet tape. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. Always use the cooling fan as mentioned before because your print will be much better with it, you'll see. I don't use a fan for abs printing. This will start the cooling fan at the height you indicate. These fans allow for consistent airflow around the hotends and quickly cools down the plastic. The best abs print temperature is not as elusive as you may think. 06.03.2021 · the perfect abs print & bed temperature... We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification.

When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. Always use the cooling fan as mentioned before because your print will be much better with it, you'll see. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. If your printer has a fan you should enable cooling in the print settings. These fans allow for consistent airflow around the hotends and quickly cools down the plastic. The recommended bed temperature for abs is 110°c. The fans are very useful when printing abs since the printing deals with extreme hot temperatures. It might be possible to use a fan to cool the print, say when a layer gets. 22.04.2014 · in order to print with abs, you need a temperature controlled bed. These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped.. It might be possible to use a fan to cool the print, say when a layer gets.

These fans allow for consistent airflow around the hotends and quickly cools down the plastic. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan. The fans are very useful when printing abs since the printing deals with extreme hot temperatures. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped. However, this is not the case when printing the first few layers of abs. These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature.

29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling. The fans are very useful when printing abs since the printing deals with extreme hot temperatures. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. The best abs print temperature is not as elusive as you may think. 29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling. However, this is not the case when printing the first few layers of abs. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan... When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped.

The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. The recommended bed temperature for abs is 110°c. The fans are very useful when printing abs since the printing deals with extreme hot temperatures.. 29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling.

I don't use a fan for abs printing.. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan.. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked.

Always use the cooling fan as mentioned before because your print will be much better with it, you'll see. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion. However, this is not the case when printing the first few layers of abs. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped. 06.03.2021 · the perfect abs print & bed temperature. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan. The recommended bed temperature for abs is 110°c. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again.. However, this is not the case when printing the first few layers of abs.

Always use the cooling fan as mentioned before because your print will be much better with it, you'll see.. When printing abs, users generally print with the part cooling fan off to maximize layer adhesion.. 29.03.2019 · i think the fan off for abs is a fairly old idiom from when printers weren't commonly enclosed, hotends would not be able to get that hot and blasting cold air across a print was cooling.

It might be possible to use a fan to cool the print, say when a layer gets. It might be possible to use a fan to cool the print, say when a layer gets. If your printer has a fan you should enable cooling in the print settings. These fans allow for consistent airflow around the hotends and quickly cools down the plastic. It might be possible to use a fan to cool the print, say when a layer gets.

It might be possible to use a fan to cool the print, say when a layer gets... This will start the cooling fan at the height you indicate. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. However, this is not the case when printing the first few layers of abs. If your printer has a fan you should enable cooling in the print settings. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped. Read on to learn all about the best print & bed temperatures for abs!.. The recommended bed temperature for abs is 110°c.

This will start the cooling fan at the height you indicate. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan. The recommended bed temperature for abs is 110°c. We still like to have our minimal layer time set to 20 seconds, but the cooling fan is unchecked. However, this is not the case when printing the first few layers of abs. When i first 3d printed for abs without any cooling settings and extra fans, i noticed that the quality of my model degraded and the edges and details were warped. This will start the cooling fan at the height you indicate. Instead of printing directly on the glass, it's better to print with kapton/pet tape. The fans are very useful when printing abs since the printing deals with extreme hot temperatures.. If you get meltdown artifacts, like typically on the chimney of a benchy, you might need to increase the minimum layer time, i usually run a rather long minimum layer time of around 25 seconds to avoid pumping too much thermal energy into a small section in too short of a time.

The best abs print temperature is not as elusive as you may think. This will start the cooling fan at the height you indicate. I don't use a fan for abs printing. These fans allow for consistent airflow around the hotends and quickly cools down the plastic. If your printer has a fan you should enable cooling in the print settings. Read on to learn all about the best print & bed temperatures for abs! We have read more than often that cooling fans help in settling each layer faster by surging the speed of solidification. The problem you're having is that when you're printing a small area layer, such as those near the top of the pyramid, the plastic doesn't have time to cool before the hot nozzle is there adding heat and plastic again. The best abs print temperature is not as elusive as you may think. These days we have a lot more control, and in an enclosure you should be able to cool using a pretty high ambient temperature. And then finally the last section in the advanced tab is the ability to activate and tweak the active cooling fan.. This will start the cooling fan at the height you indicate.